Welcome, dear reader! Are you looking to optimize your supply chain management process and streamline your business operations? Implementing an Enterprise Resource Planning (ERP) system can be the solution you are seeking. By integrating all facets of your supply chain – from procurement to manufacturing to distribution – into one comprehensive platform, ERP can help you enhance efficiency, reduce costs, and improve decision-making. In this article, we will explore the steps involved in implementing ERP for supply chain management and how it can benefit your organization.

Understanding ERP Systems for Supply Chain Management

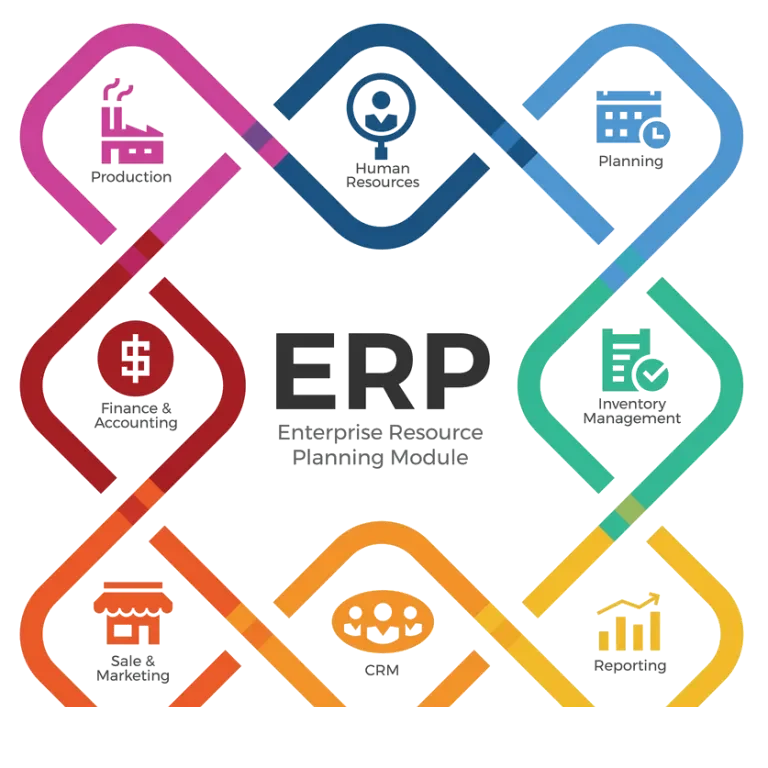

When it comes to managing a supply chain effectively, businesses need a reliable system in place to handle all the moving parts. This is where Enterprise Resource Planning (ERP) systems come into play. ERP systems are software solutions that integrate various functions of a business, including inventory management, procurement, production planning, customer relationship management, and more, into one centralized platform.

ERP systems are essential for supply chain management because they provide real-time visibility into all aspects of the supply chain. This visibility allows businesses to track inventory levels, monitor production schedules, and analyze customer demand more effectively. By having all this information in one place, businesses can make informed decisions that will ultimately improve efficiency and reduce costs.

One of the key benefits of using an ERP system for supply chain management is the automation of processes. ERP systems can streamline workflows by automating repetitive tasks, such as order processing, invoicing, and inventory tracking. This not only saves time but also reduces the risk of errors that can occur with manual data entry.

Additionally, ERP systems provide better collaboration and communication within the supply chain. With all departments working within the same system, employees can easily share information and collaborate on projects in real-time. This ensures that everyone is on the same page and working towards the same goals, ultimately leading to a more efficient and effective supply chain.

Furthermore, ERP systems offer advanced reporting and analytics capabilities. Businesses can generate customized reports and dashboards to analyze key performance indicators (KPIs) and make data-driven decisions. This insight allows businesses to identify areas for improvement and optimize their supply chain processes for better performance.

Overall, ERP systems play a crucial role in supply chain management by providing a comprehensive solution for businesses to manage their operations more effectively. With real-time visibility, process automation, improved collaboration, and advanced analytics, ERP systems help businesses streamline their supply chain processes and drive growth in today’s competitive market.

Benefits of Implementing ERP in Supply Chain Operations

Implementing an Enterprise Resource Planning (ERP) system in supply chain operations can offer a multitude of advantages for businesses looking to streamline processes, improve efficiency, and drive growth. Below are some key benefits of implementing ERP in the supply chain:

1. Enhanced Visibility: ERP systems provide real-time visibility into all aspects of the supply chain, allowing businesses to track inventory levels, monitor production processes, and optimize shipping and delivery schedules. This increased visibility helps businesses make informed decisions and respond quickly to changing market conditions.

2. Improved Collaboration: One of the most significant benefits of implementing ERP in the supply chain is improved collaboration among different departments and stakeholders. By centralizing data and communication channels, ERP systems enable seamless collaboration between sales, production, procurement, and logistics teams. This collaboration leads to better coordination, reduced lead times, and increased overall efficiency in supply chain operations.

3. Cost Savings: ERP systems help businesses identify cost-saving opportunities by optimizing inventory levels, reducing excess inventory, and negotiating better terms with suppliers. By streamlining processes and eliminating inefficiencies, businesses can reduce operational costs and improve their bottom line.

4. Compliance and Risk Management: With increasing regulatory requirements and the growing complexity of global supply chains, compliance and risk management have become critical factors for businesses. ERP systems help businesses stay compliant with regulations, track and mitigate risks, and ensure the integrity of their supply chain operations.

5. Enhanced Customer Service: By improving visibility, collaboration, and efficiency in supply chain operations, ERP systems enable businesses to deliver products to customers faster and more accurately. This leads to higher customer satisfaction, repeat business, and a competitive edge in the market.

6. Scalability and Growth: As businesses expand and grow, they need scalable solutions that can adapt to their changing needs. ERP systems are designed to scale with businesses, allowing them to add new functionalities, users, and locations as they grow. This scalability ensures that businesses can continue to operate efficiently and effectively as they expand their operations.

7. Data-driven Decision Making: ERP systems provide businesses with valuable insights and analytics that enable data-driven decision-making. By analyzing key performance indicators, trends, and forecasts, businesses can make informed decisions to optimize processes, reduce costs, and drive growth in their supply chain operations.

In conclusion, implementing an ERP system in supply chain operations can bring a wide range of benefits, including enhanced visibility, improved collaboration, cost savings, compliance and risk management, enhanced customer service, scalability and growth, and data-driven decision making. By leveraging the power of ERP, businesses can modernize their supply chain operations, stay competitive in the market, and drive long-term success.

Key Features to Look for in an ERP System for Supply Chain Management

When considering an ERP system for supply chain management, there are several key features that you should look for to ensure that the system is able to meet the unique needs of your business. These features will help you streamline processes, improve visibility, and ultimately drive better decision-making:

1. Integration Capabilities: One of the most important features to look for in an ERP system for supply chain management is strong integration capabilities. The system should be able to seamlessly integrate with other software applications that your business uses, such as inventory management systems, warehouse management systems, and customer relationship management (CRM) systems. This will ensure that data flows smoothly between different areas of your business, helping to avoid silos of information and improve overall efficiency.

2. Real-Time Visibility: Another crucial feature to look for in an ERP system for supply chain management is real-time visibility. The system should provide you with up-to-date information on inventory levels, order status, shipment tracking, and other key metrics. This real-time data will allow you to make more informed decisions and quickly respond to changes in demand or supply, helping to reduce lead times and improve customer satisfaction.

3. Advanced Analytics and Reporting: In addition to real-time visibility, an ERP system for supply chain management should also offer advanced analytics and reporting capabilities. These features will allow you to analyze historical data, identify trends, and forecast future demand more accurately. By leveraging these insights, you can optimize inventory levels, reduce stockouts, and improve overall supply chain performance. Look for a system that offers customizable reports, dashboards, and forecasting tools to help you visualize and interpret your data effectively.

4. Scalability and Flexibility: As your business grows and evolves, you need an ERP system that can scale with you. Look for a system that is flexible enough to adapt to changing business needs, whether that means adding new users, expanding into new markets, or integrating new functionalities. Scalability is especially important for supply chain management, as it will help you accommodate fluctuations in demand and adjust your operations accordingly.

5. Supplier Collaboration Tools: Effective supplier collaboration is key to a successful supply chain. Look for an ERP system that offers tools for managing supplier relationships, communicating with vendors, and sharing information securely. These collaboration features will help you build stronger partnerships with your suppliers, improve communication, and enhance overall supply chain efficiency.

By focusing on these key features when evaluating ERP systems for supply chain management, you can choose a solution that will help you streamline processes, improve visibility, and drive better business outcomes. Consider your specific needs and requirements, and look for a system that offers the right mix of features to support your supply chain operations effectively.

Challenges and Solutions of Integrating ERP with Supply Chain

Integrating ERP (Enterprise Resource Planning) with the supply chain can be a complex process that comes with its own set of challenges. One of the main challenges companies face when implementing ERP for supply chain management is the cost. ERP systems can be expensive to implement and maintain, especially for small and medium-sized businesses. Additionally, integrating ERP with existing supply chain systems can be time-consuming and require significant resources.

Another challenge companies face is the integration of different systems and data sources. ERP systems may not always be compatible with legacy systems or systems used by suppliers and partners in the supply chain. This can lead to data silos and inefficiencies in communication and collaboration between different parts of the supply chain.

In addition, there is a challenge in ensuring data accuracy and consistency across the supply chain. Different departments within a company may have different data sources and systems, leading to inconsistencies in data reporting and decision-making. This can result in delays in order processing, inventory management issues, and ultimately impact the overall efficiency of the supply chain.

One solution to these challenges is to invest in a cloud-based ERP system. Cloud-based ERP systems are typically more cost-effective than on-premise systems and offer greater flexibility and scalability. They can also be easier to integrate with other systems and data sources, making it easier to share information across the supply chain.

Another solution is to focus on data integration and data quality. Companies can invest in data integration tools and technologies to help ensure that data is accurate and consistent across different systems and departments. This can help improve communication and collaboration within the supply chain and streamline processes.

Furthermore, companies can also invest in training and education for employees to help them better understand how to use ERP systems effectively. By providing employees with the necessary skills and knowledge, companies can help ensure a smooth implementation and integration of ERP with the supply chain.

In conclusion, integrating ERP with the supply chain comes with its own set of challenges, but there are solutions available to help address these challenges. By investing in the right technology, focusing on data integration and quality, and providing employees with the necessary training, companies can successfully implement ERP for supply chain management and improve overall efficiency and productivity.

Steps to Successful Implementation of ERP in Supply Chain Operations

Implementing an ERP system in supply chain operations can be a complex process, but with careful planning and execution, it can lead to significant improvements in efficiency and cost savings. Here are five key steps to ensure a successful implementation:

1. Define Clear Objectives: Before implementing an ERP system, it is essential to define clear objectives and goals for the project. This will help to guide the implementation process and ensure that all stakeholders are aligned on what they aim to achieve with the new system. Whether the objective is to streamline inventory management, improve demand forecasting, or enhance communication with suppliers, having clear goals will provide direction throughout the implementation process.

2. Conduct a Comprehensive Business Process Analysis: To successfully implement an ERP system in supply chain operations, it is crucial to conduct a thorough analysis of existing business processes. This will help identify inefficiencies, bottlenecks, and areas for improvement that can be addressed through the new system. By understanding current workflows and pain points, organizations can design the ERP system to streamline operations and enhance overall efficiency.

3. Select the Right ERP Solution: Choosing the right ERP solution is a critical step in the implementation process. Organizations should consider factors such as scalability, customization options, integration capabilities, and vendor support when evaluating ERP systems. It is essential to select a solution that aligns with the organization’s business requirements and can effectively support supply chain operations.

4. Develop a Detailed Implementation Plan: Once the ERP solution has been selected, it is important to develop a detailed implementation plan that outlines the specific steps, timeline, and responsibilities for the project. This plan should include tasks such as data migration, system configuration, user training, and testing to ensure a smooth transition to the new system. By breaking down the implementation process into manageable steps, organizations can minimize disruptions and address any challenges that arise during the transition.

5. Provide Ongoing Training and Support: One of the most critical aspects of a successful ERP implementation is ongoing training and support for end-users. It is essential to provide comprehensive training programs to ensure that employees understand how to use the new system effectively. Additionally, organizations should offer ongoing technical support to address any issues or questions that may arise after the system goes live. By investing in proper training and support, organizations can maximize the benefits of their ERP system and ensure long-term success.

By following these five steps, organizations can successfully implement an ERP system in their supply chain operations and unlock the full potential of their supply chain management processes.

Originally posted 2024-04-21 04:04:49.