Welcome to our guide on implementing ERP systems in the food processing industry! Whether you’re a small family-owned business or a large manufacturing facility, utilizing an ERP system can streamline your operations and improve overall efficiency. In this article, we’ll cover the benefits of ERP systems in the food processing industry and provide a step-by-step guide on how to successfully implement one in your organization.

Understanding the Importance of ERP in Food Processing

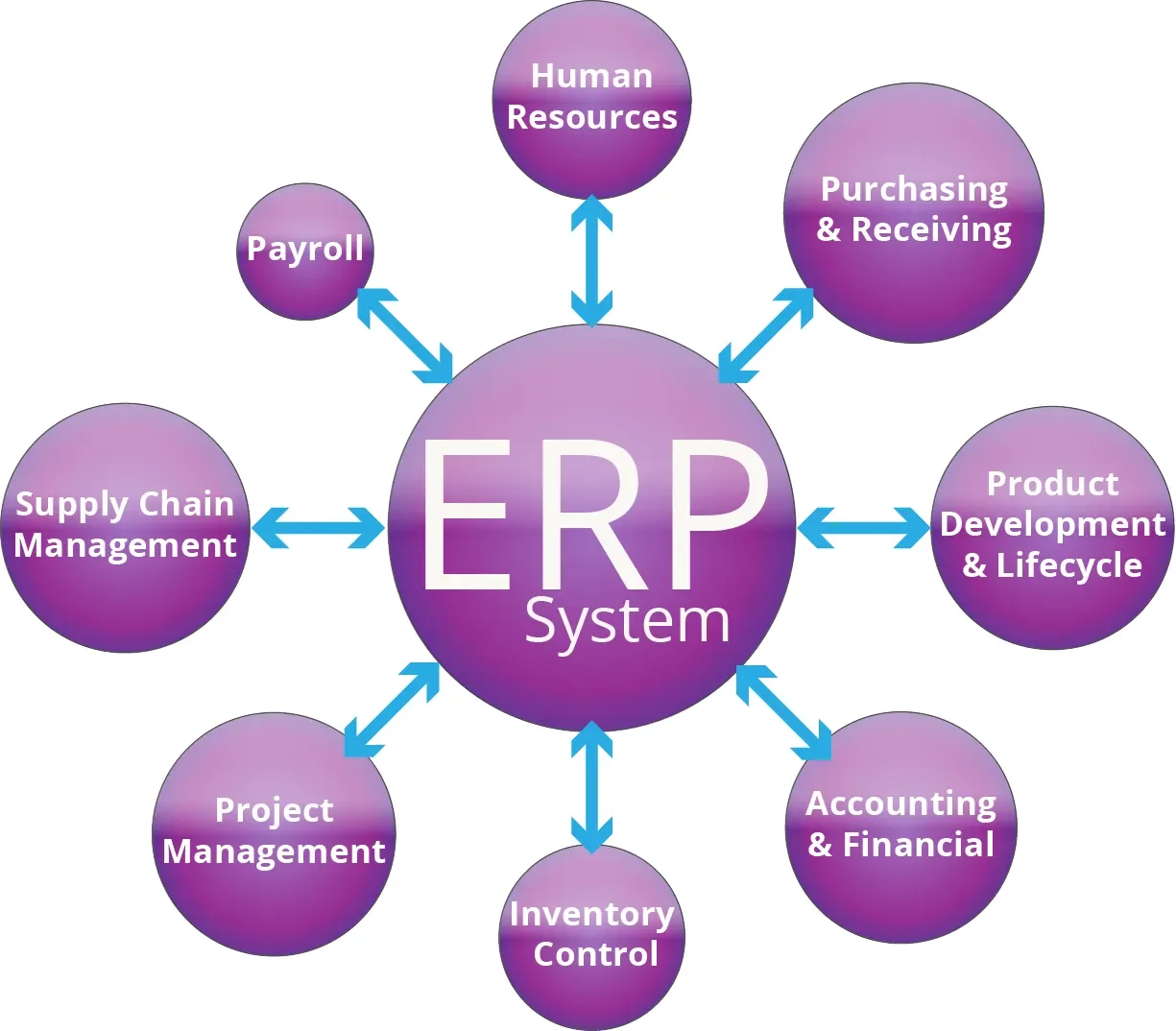

ERP, which stands for Enterprise Resource Planning, is a software system that helps businesses in managing and integrating their important operations. In the food processing industry, where efficiency and accuracy are crucial, ERP plays a significant role in streamlining processes and improving overall productivity. From managing inventory to tracking sales and finances, ERP provides a comprehensive solution that helps businesses in the food processing industry stay competitive in today’s market.

One of the key benefits of using ERP in the food processing industry is its ability to centralize data and streamline communication between different departments. With an ERP system in place, information can be easily accessed and shared across departments, eliminating the need for manual data entry and reducing the risk of errors. This not only saves time but also ensures that all employees are working with the most up-to-date information, leading to better decision-making and improved efficiency.

Another important aspect of ERP in the food processing industry is its role in inventory management. With the perishable nature of food products, it is crucial for businesses in this industry to have real-time visibility into their inventory levels. An ERP system can help in tracking inventory levels, anticipating demand, and optimizing the supply chain to prevent stockouts or overstock situations. This not only reduces wastage but also helps in meeting customer demand more effectively.

Furthermore, ERP software can help in ensuring compliance with food safety regulations and quality standards. With features like batch tracking and traceability, businesses can easily track the journey of a food product from its raw materials to the final product, making it easier to identify and address any issues that may arise. This not only helps in maintaining quality standards but also builds trust with customers and regulatory bodies.

In addition to improving operational efficiency, ERP in the food processing industry can also provide valuable insights through data analytics. By analyzing data collected from different operations, businesses can identify trends, forecast demand, and make informed decisions to drive growth and profitability. This data-driven approach is crucial in today’s competitive market, where businesses need to adapt quickly to changing consumer preferences and market dynamics.

In conclusion, ERP plays a crucial role in the food processing industry by streamlining processes, improving efficiency, ensuring compliance, and providing valuable insights through data analytics. With its comprehensive features and benefits, ERP can help businesses in this industry stay competitive, meet customer demands, and drive growth in a rapidly evolving market.

Selecting the Right ERP System for Your Food Processing Business

Choosing the right ERP system for your food processing business is crucial for streamlining operations, improving efficiency, and ensuring compliance with industry regulations. With so many options available in the market, it can be overwhelming to make a decision. Here are some key factors to consider when selecting an ERP system for your food processing business:

1. Industry-Specific Features: One of the most important factors to consider when choosing an ERP system for your food processing business is the availability of industry-specific features. A generic ERP system may not have the necessary functions and capabilities required to meet the unique needs of the food processing industry. Look for features such as lot traceability, recipe management, compliance with FDA regulations, quality control, and supply chain management.

2. Scalability: It’s important to choose an ERP system that can grow with your business. As your food processing business expands, you may need to add new products, increase production capacity, or enter new markets. Make sure the ERP system you choose is scalable and can accommodate future growth without requiring a complete overhaul of the system. Look for a solution that offers easy customization options and can be easily integrated with other software solutions.

3. Integration Capabilities: In today’s digital age, it’s essential for businesses to have a seamless flow of information between different departments and systems. Look for an ERP system that offers robust integration capabilities with other software solutions such as accounting software, inventory management systems, CRM systems, and e-commerce platforms. This will help improve communication among different departments, eliminate manual data entry errors, and streamline business processes.

4. Ease of Use: An ERP system is only effective if it is user-friendly and easy to use. Make sure the system you choose has an intuitive interface that is easy for employees to navigate and understand. Training employees on a complicated ERP system can be time-consuming and costly. Look for a system that offers comprehensive training and support to help your employees quickly adapt to the new software.

5. Cloud-Based vs. On-Premise: Another important factor to consider when selecting an ERP system for your food processing business is whether to opt for a cloud-based or on-premise solution. Cloud-based ERP systems offer the advantage of accessibility from anywhere with an internet connection, automatic updates, and lower upfront costs. On the other hand, on-premise solutions provide more control over data security and customization. Consider your business needs and budget constraints when deciding between the two options.

Choosing the right ERP system for your food processing business is a critical decision that can have a significant impact on your operations and bottom line. By considering factors such as industry-specific features, scalability, integration capabilities, ease of use, and deployment options, you can make an informed decision that will help your business thrive in the competitive food processing industry.

Implementation Process of ERP in the Food Processing Industry

The implementation process of an Enterprise Resource Planning (ERP) system in the food processing industry can be a complex yet rewarding journey. The first step in this process is to conduct a thorough analysis of the current operations and determine the specific needs and requirements of the organization. This involves identifying the key areas where the ERP system can bring the most benefit, such as inventory management, production planning, quality control, and logistics.

Once the requirements have been identified, the next step is to select the right ERP software solution that aligns with the business goals and objectives of the food processing company. It is essential to choose a system that is specifically designed for the food processing industry, as this will ensure that it meets the unique challenges and requirements of the sector.

After selecting the ERP solution, the implementation phase begins. This involves setting up the system, configuring it to meet the specific needs of the organization, and integrating it with existing systems and processes. It is crucial to involve key stakeholders from different departments in this phase to ensure that the system is implemented in a way that meets the needs of all users.

Training and education are also vital components of the implementation process. Employees at all levels of the organization need to be trained on how to use the new ERP system effectively. This training should be ongoing to ensure that employees are comfortable with the system and can maximize its benefits.

As the system goes live, it is essential to monitor its performance and make any necessary adjustments to ensure that it is operating effectively. This may involve running test scenarios, gathering feedback from users, and making modifications to the system as needed. Continuous evaluation and improvement are critical to the success of an ERP implementation in the food processing industry.

Finally, post-implementation support is crucial to the long-term success of the ERP system. This involves providing ongoing support to users, addressing any technical issues that may arise, and staying up to date with system updates and upgrades. Regular maintenance and support will help ensure that the ERP system continues to deliver value to the food processing company for years to come.

Key Features to Look for in an ERP System for Food Processing

Implementing an ERP system in the food processing industry can transform operations and streamline processes for increased efficiency and profitability. When choosing an ERP system for your food processing business, it is essential to consider the key features that will best meet your specific needs. Below are some key features to look for in an ERP system for the food processing industry:

1. Compliance Management: With strict regulations and standards in the food processing industry, it is crucial to have an ERP system that can help you maintain compliance with food safety regulations. Look for a system that offers robust compliance management features, such as tracking and documenting all processes, from sourcing ingredients to packaging and distribution.

2. Inventory Management: Efficient inventory management is essential in the food processing industry to prevent wastage and ensure timely production. An ERP system with advanced inventory management features can help you track raw materials, finished goods, and packaging materials in real-time, allowing you to optimize your inventory levels and reduce costs.

3. Traceability: Traceability is a critical aspect of food processing, as it allows you to track the entire lifecycle of a product from farm to fork. Choose an ERP system that offers comprehensive traceability features, such as batch tracking and real-time visibility into production processes. This will not only help you comply with regulations but also enable you to quickly respond to any quality or safety issues.

4. Production Planning and Scheduling: One of the most important features to look for in an ERP system for the food processing industry is robust production planning and scheduling capabilities. A system that can help you optimize production processes, plan efficient production schedules, and minimize downtime will ultimately improve productivity and profitability. Look for features such as automated scheduling, real-time resource allocation, and predictive analytics to streamline your production operations.

5. Recipe and Formula Management: Managing recipes and formulas is a critical aspect of the food processing industry, as it directly impacts product consistency and quality. An ERP system with recipe and formula management features can help you accurately track ingredients, adjust formulas for different batch sizes, and ensure consistent product quality. Look for a system that offers version control, ingredient substitution capabilities, and real-time recipe costing.

6. Mobile Access: In today’s fast-paced environment, having access to real-time data is essential for making informed decisions. Look for an ERP system that offers mobile access capabilities, allowing you to access critical information anytime, anywhere. With mobile access, you can monitor production processes, track inventory levels, and stay connected with your team even when you’re on the go.

By considering these key features when choosing an ERP system for your food processing business, you can ensure that you select a system that meets your specific needs and helps you achieve your goals of increased efficiency, compliance, and profitability.

Benefits of Using ERP in Food Processing Industry

The food processing industry faces unique challenges such as tight regulations, high competition, perishable products, fluctuating raw material costs, and constantly changing consumer preferences. In such a complex environment, implementing an ERP system can bring several benefits to companies in the food processing industry.

One of the key advantages of using ERP in the food processing industry is improved traceability. With an ERP system, companies can track products from the sourcing of raw materials to the delivery of finished goods. This level of traceability is crucial for ensuring food safety and compliance with regulations. In case of a recall, ERP systems can quickly identify affected products and streamline the recall process, minimizing the impact on both consumers and the company.

Another benefit of using ERP in the food processing industry is increased efficiency and productivity. ERP systems can automate repetitive tasks, streamline processes, and provide real-time insights into operations. This allows companies to make quicker and more informed decisions, reduce waste, and optimize their resources. By eliminating manual data entry and integrating various departments, ERP systems can also reduce errors and improve overall accuracy.

ERP systems can also help food processing companies enhance their inventory management. By providing a real-time view of inventory levels, ERP systems enable companies to better manage their stock, prevent stockouts, and reduce excess inventory. This not only improves operational efficiency but also helps companies save costs and minimize wastage. With accurate inventory data, companies can also better plan production schedules and respond to changes in demand.

Furthermore, ERP systems can support better supply chain management in the food processing industry. By integrating suppliers, manufacturers, distributors, and retailers into a single platform, ERP systems enable companies to optimize their supply chain, reduce lead times, and improve collaboration. This can result in better coordination, faster response times, and ultimately, improved customer satisfaction. Additionally, with better visibility into the supply chain, companies can identify bottlenecks, optimize workflows, and reduce costs.

Lastly, ERP systems can help food processing companies comply with industry regulations and standards. With built-in compliance features, ERP systems can ensure that companies meet all the necessary requirements, such as labeling, packaging, and quality control. This not only helps companies avoid fines and penalties but also enhances their reputation and builds trust with customers. By providing a centralized platform for data management and reporting, ERP systems make it easier for companies to demonstrate compliance and maintain high quality standards.

Originally posted 2024-04-21 05:58:48.